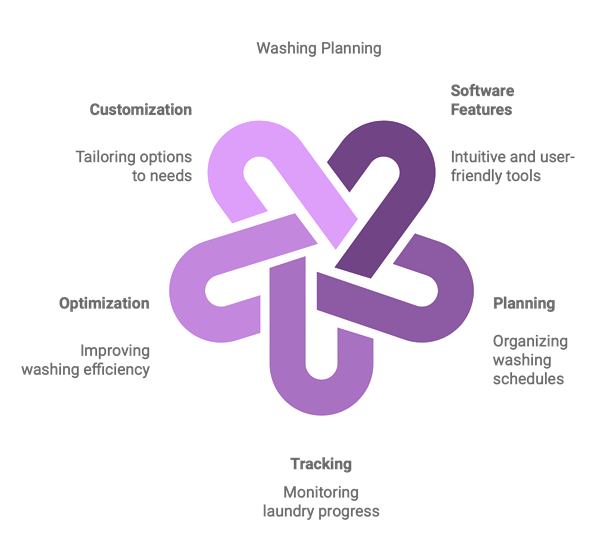

Benefits of Using Software for Garment Washing Planning

Enhanced Efficiency

Automation of washing schedules and resource management streamlines operations, reducing lead times and optimizing workflows.

Improved Accuracy

Software minimizes human error in planning and execution, ensuring that washing processes are carried out according to precise specifications.

Optimized Resource Allocation

Effective management of washing machines, detergents, and labor ensures that resources are utilized efficiently, maximizing productivity and minimizing downtime.

Real-Time Monitoring

Many software solutions provide live updates on the washing process, allowing for immediate adjustments and better responsiveness to any issues that arise.

Data-Driven Insights

Analytics features offer valuable insights into washing efficiency, water usage, and chemical consumption, helping manufacturers identify trends and areas for improvement.

Customizable Reporting

Users can generate reports tailored to specific needs, such as wash cycle efficiency, resource usage, and production summaries, aiding informed decision-making.

Sustainability Tracking

Some software options include features for tracking environmental impact, such as water and energy consumption, helping companies adopt more sustainable practices.

Cost Savings

By optimizing washing processes and reducing waste, manufacturers can lower operational costs, ultimately enhancing profitability.

Better Collaboration

Integrated communication tools facilitate coordination among teams, suppliers, and vendors, reducing misunderstandings and improving overall workflow.

Scalability

As production demands grow, washing planning software can easily adapt to accommodate increased volume and complexity without sacrificing quality.

By utilizing software for garment washing planning, manufacturers can enhance their operational efficiency, improve product quality, and maintain a competitive edge in the apparel industry.

How Software Generates Smart Report Analytics in Garment Washing Planning

Garment washing planning software employs advanced data analytics to create insightful reports that enhance operational efficiency. Here’s how it works

Data Collection

The software gathers data from various stages of the washing process, including wash cycles, machine performance, chemical usage, and labor efficiency.

Real-Time Monitoring

By tracking operations in real time, the software captures essential metrics such as wash times, water consumption, and machine downtime, providing an accurate overview of performance.

Automated Analysis

Advanced algorithms analyze the collected data to identify trends, patterns, and discrepancies, enabling quick insights while minimizing the risk of human error

Customizable Reporting

Users can generate reports tailored to specific needs, such as efficiency summaries, resource usage, and production statuses, helping stakeholders focus on the most relevant information.

Visualization Tools

Data visualization features, including graphs and charts, simplify complex information, making it easier to interpret. Visual aids highlight key performance indicators (KPIs) and areas that need attention.

Comparative Analysis

The software enables comparisons across different time periods, wash lines, or shifts, allowing manufacturers to evaluate performance changes and identify successful practices.

Predictive Analytics

Some solutions incorporate predictive analytics to forecast future washing needs and potential challenges based on historical data, facilitating proactive planning and resource management.

Integration with Other Systems

Many garment washing planning solutions can integrate with other enterprise systems, such as inventory and production management, providing a comprehensive view of operations.

User-Friendly Dashboards

Intuitive dashboards present key metrics and analytics in an easily digestible format, allowing decision-makers to quickly assess performance and make informed choices.

Actionable Insights

The ultimate goal of smart report analytics is to provide actionable insights. Manufacturers can leverage this data to make strategic decisions, optimize workflows, and enhance overall productivity.

By utilizing smart report analytics, garment washing planning software empowers manufacturers to improve efficiency, reduce costs, and maintain high-quality standards in their washing operations.

Garments Chemical Planning Software

Garments chemical planning software is a specialized tool designed to streamline the management of chemicals and dyes used in the apparel manufacturing process. This software optimizes the planning, usage, and tracking of chemicals, ensuring compliance with safety regulations while enhancing efficiency and sustainability.

Chemical Inventory Management

The software provides robust inventory tracking capabilities, allowing manufacturers to monitor the stock levels of various chemicals and dyes, preventing shortages and overstock situations.

Usage Tracking

It tracks the consumption of chemicals in real time, helping manufacturers analyze usage patterns and optimize their formulations to reduce waste and improve cost-efficiency.

Recipe Management

Users can create, store, and manage dyeing and finishing recipes, ensuring consistency in color and quality across different production batches.

Regulatory Compliance

The software helps ensure compliance with local and international regulations regarding the use and disposal of chemicals, minimizing the risk of legal issues and environmental impact.

Data Analytics

Advanced analytics features provide insights into chemical usage trends, costs, and performance metrics, enabling manufacturers to make informed decisions and enhance their production processes.

Integration with Other Systems

The software can integrate seamlessly with other production management systems, such as inventory, scheduling, and quality control, providing a holistic view of operations.

User-Friendly Interface

Designed with usability in mind, the software features an intuitive interface that allows users to navigate easily and access necessary information quickly.

Sustainability Tracking

Many solutions include features for tracking the environmental impact of chemical usage, helping manufacturers implement more sustainable practices.

Real-Time Reporting

Users can generate customizable reports that provide valuable insights into chemical usage, costs, and compliance status, facilitating better planning and management.

Training and Support

Comprehensive training resources and customer support help users maximize the software’s capabilities, ensuring effective implementation and ongoing success.

By utilizing garments chemical planning software, manufacturers can enhance operational efficiency, ensure regulatory compliance, and promote sustainability in their chemical usage, ultimately improving product quality and reducing costs.

Benefits of Using Software for Garment Chemical Planning

Improved Efficiency

Automation of chemical management processes streamlines operations, reducing the time and effort required for tracking and planning chemical usage.

Accurate Inventory Management

Software provides real-time visibility into chemical inventory levels, helping manufacturers avoid shortages and overstock situations, which can disrupt production.

Cost Control

By optimizing chemical usage and reducing waste, the software helps manufacturers lower operational costs, contributing to better overall profitability.

Enhanced Compliance

Many software solutions are designed to ensure adherence to local and international regulations regarding chemical use and disposal, minimizing legal risks and promoting safety.

Data-Driven Insights

Advanced analytics capabilities provide valuable insights into chemical consumption patterns, costs, and performance metrics, enabling informed decision-making.

Recipe Standardization

The software allows for the creation and management of consistent dyeing and finishing recipes, ensuring uniformity in color and quality across different production batches.

Sustainability Tracking

Features that monitor the environmental impact of chemical usage help manufacturers implement more sustainable practices and improve their corporate responsibility.

Real-Time Reporting

Users can generate customizable reports on chemical usage, costs, and compliance status, facilitating better planning and management.

Integration Capabilities

Many chemical planning software solutions can seamlessly integrate with other production management systems, providing a comprehensive view of operations.

User-Friendly Interface

Designed for ease of use, the software typically features an intuitive interface that allows users to navigate and access information quickly, reducing training time.

By leveraging software for garment chemical planning, manufacturers can enhance operational efficiency, improve product quality, ensure compliance, and promote sustainability in their chemical usage.

How Software Generates Smart Report Analytics in Garment Chemicals Planning

Garment chemicals planning software employs advanced data analytics to produce insightful reports that enhance operational efficiency. Here’s how it works.

Data Collection

The software gathers data from various stages of the chemical usage process, including inventory levels, consumption rates, and application methods.

Real-Time Monitoring

By tracking chemical usage in real time, the software captures key metrics such as stock levels, order frequencies, and waste percentages, providing an accurate snapshot of performance.

Automated Analysis

Advanced algorithms analyze the collected data to identify trends, patterns, and anomalies, allowing for quick insights while minimizing human error.

Customizable Reporting

Users can generate reports tailored to specific needs, such as usage summaries, cost analyses, and compliance reports, enabling stakeholders to focus on the most relevant information.

Data Visualization

Visualization tools, including graphs and charts, help simplify complex data, making it easier to interpret. These visual aids highlight key performance indicators (KPIs) and areas that require attention.

Comparative Analysis

The software allows for comparisons across different time periods, production lines, or chemical types, enabling manufacturers to evaluate performance changes and identify successful strategies.

Predictive Analytics

Some solutions incorporate predictive analytics to forecast future chemical needs and potential challenges based on historical data, facilitating proactive planning and resource management.

Integration with Other Systems

Many garment chemicals planning solutions can integrate with other enterprise systems, such as production and inventory management, providing a comprehensive view of operations.

User-Friendly Dashboards

Intuitive dashboards present key metrics and analytics in an easily digestible format, allowing decision-makers to quickly assess performance and make informed choices.

Actionable Insights

The ultimate goal of smart report analytics is to provide actionable insights. Manufacturers can leverage this data to make strategic decisions, optimize workflows, and enhance overall productivity.

By utilizing smart report analytics, garment chemicals planning software empowers manufacturers to improve efficiency, reduce costs, and maintain high-quality standards in their chemical management processes.