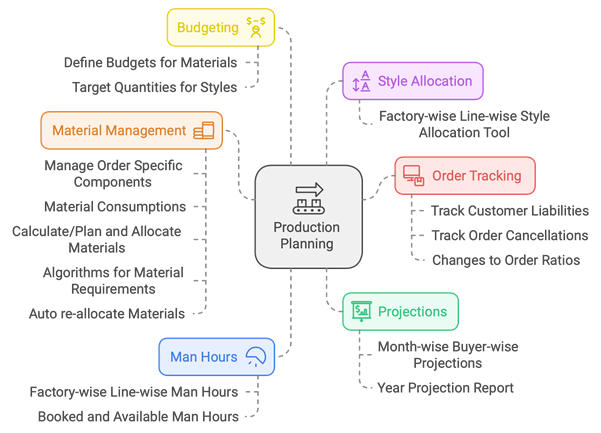

Production Planning Features

Garments production planning software is a specialized tool designed to streamline and optimize the manufacturing process in the apparel industry. This software helps businesses manage their production schedules, inventory levels, and resource allocation more efficiently.

Production Scheduling

Automates the planning of production runs, ensuring that timelines are met while minimizing downtime and resource waste.

Inventory Management

Tracks raw materials and finished goods, helping businesses maintain optimal stock levels and avoid overproduction or shortages.

Workforce Management

Manages labor resources by scheduling shifts and tracking employee productivity, ensuring that the right number of workers is available when needed.

Data Analytics

Provides insights into production efficiency, cost management, and order fulfillment rates, enabling informed decision-making.

Collaboration Tools

Facilitates communication among teams, suppliers, and vendors, improving coordination and reducing errors in the production process.

Customization Options

Allows businesses to tailor the software to their specific needs, accommodating various types of garments and production processes. Overall, garments production planning software enhances operational efficiency, reduces costs, and helps companies respond quickly to market demands, ultimately driving profitability in the competitive apparel industry.

Benefits of Using Software for garment production Planning

Enhanced Efficiency

Automation of scheduling and resource management streamlines production processes, significantly reducing lead times and improving workflow.

Increased Accuracy

Software minimizes human errors in planning, ensuring that production schedules and inventory levels align closely with actual needs.

Optimized Resource Allocation

Effective management of labor and machinery ensures that resources are used efficiently, reducing downtime and maximizing productivity.

Real-Time Tracking

Many software solutions provide live updates on production status, enabling immediate adjustments and better responsiveness to changes in demand.

Improved Inventory Management

Integrated inventory tracking helps maintain optimal stock levels of raw materials and finished products, minimizing waste and preventing shortages.

Data-Driven Insights

Analytics tools offer valuable insights into production metrics, helping manufacturers identify inefficiencies, forecast trends, and make informed decisions.

Scalability

As businesses grow, production planning software can easily adapt to increased demands, ensuring that operations remain efficient without sacrificing quality.

Cost Savings

By optimizing workflows and reducing waste, manufacturers can lower operational costs, ultimately enhancing profitability.

Better Collaboration and Communication

Improved communication tools foster collaboration among teams, suppliers, and vendors, reducing misunderstandings and enhancing overall coordination.

Customization and Flexibility

Many software options allow for customization to meet specific business needs, accommodating various garment types and production processes.

By adopting software for garment production planning, manufacturers can boost operational efficiency, enhance product quality, and maintain a competitive edge in the fast-paced fashion industry.

How Software Generates Smart Report Analytics in Garment Production Planning

Garment production planning software harnesses advanced data analytics to create insightful reports that enhance operational efficiency. Here’s how it works

Data Collection

The software gathers data from various stages of the production process, including scheduling, resource allocation, labor efficiency, and material usage.

Real-Time Monitoring

By tracking production in real time, the software captures critical metrics such as production rates, cycle times, and machine downtime, providing an accurate view of performance.

Automated Analysis

Advanced algorithms process the collected data to identify trends, patterns, and anomalies, enabling quick insights while reducing the risk of human error.

Customizable Reporting

Users can generate reports tailored to their specific needs, such as production summaries, efficiency metrics, and inventory levels, helping stakeholders focus on the most relevant information.

Visualization Tools

Data visualization features, including graphs and charts, simplify complex information, making it easier to interpret. These visual aids highlight key performance indicators (KPIs) and areas that need attention.

Comparative Analysis

The software allows comparisons across different time periods, production lines, or shifts, enabling manufacturers to evaluate performance changes and identify successful strategies.

Predictive Analytics

Some software solutions incorporate predictive analytics to forecast future production needs and potential challenges based on historical data, facilitating proactive planning and resource management.

Integration with Other Systems

Many garment production planning solutions can integrate with other enterprise systems, such as inventory management and supply chain platforms, providing a comprehensive view of operations.

User-Friendly Dashboards

Intuitive dashboards present key metrics and analytics in an easily digestible format, allowing decision-makers to quickly assess performance and make informed choices.

Actionable Insights

The ultimate goal of smart report analytics is to provide actionable insights. Manufacturers can leverage this data to make strategic decisions, optimize workflows, and enhance overall productivity.

By utilizing smart report analytics, garment production planning software empowers manufacturers to improve efficiency, reduce costs, and maintain high-quality standards throughout their production processes.

Stitch Planning

Garments stitch planning software is an innovative tool designed to enhance the efficiency and accuracy of the stitching process in apparel manufacturing. This software focuses on optimizing the sequence and method of stitching operations, ensuring high-quality production and reduced lead times.

Stitching Sequence Optimization

Automates the planning of stitch sequences to minimize fabric waste and improve workflow, helping manufacturers achieve better productivity.

Pattern and Design Integration

Allows users to upload garment patterns and designs, enabling seamless alignment of stitching plans with the specific requirements of each item.

Resource Allocation

Helps manage sewing machine usage and labor assignments, ensuring that the right resources are available at the right time to meet production goals.

Real-time Monitoring

Provides live updates on production progress, enabling quick adjustments to the stitching plan if necessary to address any delays or issues.

Data Analytics

Offers insights into stitching efficiency, cycle times, and potential bottlenecks, allowing manufacturers to identify areas for improvement.

User-friendly Interface

Designed with ease of use in mind, making it accessible for operators and planners alike, regardless of their technical expertise. Overall, garments stitch planning software is essential for modern apparel manufacturers looking to streamline their operations, improve product quality, and respond swiftly to changing market demands. By optimizing the stitching process, this software contributes to increased efficiency and enhanced profitability in the competitive fashion industry.

Benefits of Using Software for Stitching Planning

Using software for stitching planning in apparel manufacturing offers numerous benefits that can significantly enhance efficiency and productivity. Here are some key advantages

Improved Efficiency

Automation of stitching schedules minimizes manual planning, allowing manufacturers to streamline operations and reduce lead times.

Optimized Resource Allocation

Software helps allocate resources, such as sewing machines and labor, effectively. This ensures that the right equipment and personnel are available for each task, reducing downtime.

Enhanced Accuracy

By automating stitch sequences and planning, the software reduces the likelihood of human error, ensuring that garments are produced according to precise specifications.

Better Inventory Management

Integrated inventory tracking allows manufacturers to maintain optimal stock levels of materials, reducing waste and avoiding shortages during production.

Real-time Monitoring

Many software solutions offer live tracking of production progress, enabling quick adjustments to schedules and workflows as needed, which enhances responsiveness.

Data-Driven Insights

Analytics features provide valuable insights into production metrics, helping manufacturers identify trends, inefficiencies, and areas for improvement, leading to better decision-making.

Customization and Flexibility

Many stitching planning software options allow for customization to fit specific business needs, accommodating different types of garments and production methods.

Improved Communication

Collaborative tools facilitate better communication among team members, suppliers, and vendors, reducing misunderstandings and errors throughout the production process.

Cost Savings

By optimizing production processes and reducing waste, manufacturers can lower operational costs, ultimately improving profitability

Scalability

As businesses grow, stitching planning software can easily adapt to increased production demands, allowing for seamless scaling without sacrificing efficiency.

Overall, adopting stitching planning software empowers apparel manufacturers to operate more effectively, meet market demands, and maintain high-quality standards in their products.

How Software Generates Smart Report Analytics in Stitching Planning

Stitching planning software leverages advanced data analytics to generate insightful reports that help manufacturers optimize their operations. Here’s how it works

Data Collection

The software collects data from various stages of the stitching process, including production schedules, machine utilization, labor efficiency, and material usage.

Real-Time Monitoring

By tracking production in real-time, the software captures relevant metrics, such as cycle times, output rates, and downtime incidents, providing an accurate view of current performance.

Automated Analysis

Advanced algorithms analyze the collected data to identify trends, patterns, and anomalies. This automation allows for quick processing and reduces the likelihood of human error.

Customizable Reports

Users can generate customizable reports tailored to specific needs, such as performance summaries, resource allocation efficiency, and production forecasts. This flexibility helps stakeholders focus on the most relevant information.

Visualization Tools

The software often includes data visualization features, such as graphs and charts, which make complex data easier to understand at a glance. Visual representations can highlight key performance indicators (KPIs) and areas needing attention.

Comparative Analysis

By comparing data across different time periods, production lines, or shifts, the software enables manufacturers to evaluate performance changes and identify successful strategies or areas for improvement.

Predictive Analytics

Some software solutions employ predictive analytics to forecast future production needs and potential challenges based on historical data. This foresight helps in proactive planning and resource allocation.

Integration with Other Systems

Many stitching planning software solutions can integrate with other enterprise systems, such as inventory management and supply chain platforms. This integration provides a holistic view of operations and enhances the accuracy of reports.

User-Friendly Dashboards

Intuitive dashboards present key metrics and analytics in an easily digestible format, allowing decision-makers to quickly assess performance and make informed choices.

Actionable Insights

The ultimate goal of smart report analytics is to provide actionable insights. Manufacturers can use the data to make strategic decisions, optimize processes, and improve overall productivity.

By harnessing the power of smart report analytics, stitching planning software enables manufacturers to enhance their operational efficiency, reduce costs, and maintain high-quality standards in their production processes.

Printing Planning

Garments printing planning software is a specialized tool designed to optimize the printing process in the apparel manufacturing industry. This software streamlines the planning and execution of printing tasks, ensuring that designs are applied efficiently and accurately to garments.

Design Integration

Allows users to upload and manage artwork and designs, ensuring compatibility with various printing methods, such as screen printing, digital printing, or sublimation.

Print Job Scheduling

Automates the scheduling of print jobs, helping manufacturers prioritize orders based on deadlines and resource availability, while minimizing downtime.

Color Management

Provides tools for managing color accuracy and consistency, ensuring that the final product matches the intended design specifications.

Resource Allocation

Helps optimize the use of printing equipment and materials, ensuring that resources are efficiently utilized to meet production demands.

Real-time Tracking

Offers visibility into the status of print jobs, enabling quick adjustments and updates to schedules as needed, thereby enhancing workflow management.

Data Analytics

Analyzes production data to identify trends, assess printing efficiency, and highlight areas for improvement, allowing manufacturers to make informed decisions.

User-friendly Interface

Designed to be intuitive, making it accessible for users at all levels, from operators to managers.

Overall, garments printing planning software is essential for apparel manufacturers aiming to enhance their printing capabilities, improve turnaround times, and maintain high-quality standards. By streamlining the printing process, this software helps businesses remain competitive in the fast-paced fashion industry.

Benefits of Using Software for garments printing Planning

Streamlined Workflow

Automation of the printing schedule and job management simplifies the workflow, reducing lead times and enhancing overall efficiency.

Improved Accuracy

Software minimizes the risk of human error in planning and execution, ensuring that designs are printed correctly and consistently.

Resource Optimization

Effective allocation of printing equipment and materials ensures that resources are utilized efficiently, maximizing productivity while minimizing waste.

Real-Time Monitoring

Many software solutions offer live tracking of print jobs, allowing for immediate adjustments to schedules and processes as needed to meet demand.

Enhanced Design Management

Users can easily upload, manage, and modify designs, ensuring that all team members have access to the latest versions and specifications.

Color Management

Advanced color management tools ensure color accuracy and consistency across prints, helping to maintain high-quality standards.

Data Analytics

Software provides insights into production metrics, helping manufacturers identify trends, assess efficiency, and make informed decisions to improve processes.

Cost Efficiency

By optimizing print runs and reducing material waste, manufacturers can lower operational costs, leading to increased profitability.

Scalability

As production needs grow, printing planning software can easily adapt to accommodate increased volume and complexity without sacrificing quality.

Better Collaboration

Integrated communication tools facilitate coordination among teams, suppliers, and clients, reducing misunderstandings and improving overall project management.

By leveraging software for garments printing planning, manufacturers can enhance their production capabilities, improve quality, and stay competitive in the dynamic apparel industry.

How Software Generates Smart Report Analytics in Printing Planning

Garment printing planning software uses advanced data analytics to create insightful reports that enhance operational efficiency. Here’s how it works

Data Collection

The software gathers information from various stages of the printing process, including job schedules, machine performance, material usage, and labor efficiency.

Real-Time Monitoring

By tracking production in real-time, the software captures essential metrics like print speeds, job completion times, and equipment downtime, providing an accurate snapshot of performance.

Automated Analysis

Advanced algorithms analyze the collected data to identify trends, patterns, and anomalies, allowing for quick processing and reducing the risk of human error.

Customizable Reporting

Users can generate reports tailored to specific needs, such as production summaries, efficiency metrics, and inventory statuses, helping stakeholders focus on the most relevant information.

Visualization Tools

Data visualization features, including charts and graphs, simplify complex information, making it easier to understand. These visual aids highlight key performance indicators (KPIs) and areas needing attention.

Comparative Analysis

The software allows comparisons across different time periods, production lines, or shifts, enabling manufacturers to evaluate performance changes and identify successful strategies.

Predictive Analytics

Some software solutions incorporate predictive analytics to forecast future production needs and potential challenges based on historical data, aiding proactive planning and resource management.

Integration with Other Systems

Many garment printing planning solutions can integrate with other enterprise systems, such as inventory and supply chain management, providing a comprehensive view of operations.

User-Friendly Dashboards

Intuitive dashboards present key metrics and analytics in an easily digestible format, enabling decision-makers to quickly assess performance and make informed choices.

Actionable Insights

The ultimate goal of smart report analytics is to provide actionable insights. Manufacturers can leverage this data to make strategic decisions, optimize workflows, and enhance overall productivity.

By utilizing smart report analytics, garment printing planning software empowers manufacturers to improve efficiency, reduce costs, and maintain high-quality standards in their printing operations.

Embroidery Planning

Garments embroidery planning software is a specialized tool designed to streamline and optimize the embroidery process in apparel manufacturing. This software enhances efficiency, accuracy, and quality control by managing the entire workflow of embroidery projects.

Design Upload and Management

Allows users to easily upload and manage embroidery designs, ensuring compatibility with various embroidery machines and formats.

Production Scheduling

Automates the scheduling of embroidery jobs, prioritizing tasks based on deadlines and available resources, which helps minimize delays and optimize workflow.

Stitch Planning

Provides detailed stitch planning tools that allow users to set parameters for thread colors, stitch types, and densities, ensuring high-quality output.

Resource Allocation

Helps optimize the use of embroidery machines and personnel, ensuring that the right equipment and staff are assigned to each project for maximum efficiency.

Real-time Monitoring

Offers live tracking of production progress, enabling users to make quick adjustments if issues arise, thus maintaining productivity.

Quality Control Features

Includes tools for checking design accuracy and stitch quality, ensuring that the final product meets design specifications and quality standards.

Data Analytics

Analyzes production metrics to identify trends, evaluate efficiency, and pinpoint areas for improvement, empowering manufacturers to make data-driven decisions.

User-friendly Interface

Designed for ease of use, making it accessible for operators and managers alike, regardless of their technical expertise.

Overall, garments embroidery planning software is essential for apparel manufacturers looking to enhance their embroidery capabilities, improve production efficiency, and maintain high standards of quality. By optimizing the embroidery process, this software helps businesses stay competitive in the dynamic fashion industry.

Benefits of Using Software for Embroidery Planning

Commercial software is any software or program that is designed and developed for licensing or sale to end users or that serves a commercial purpose. Commercial software in Bangladesh is basically, a software that provides helping hand in organizing commercial data and information regarding L/C tasks, License, Work Order, Export, Import, Report like Back to Back Liability Coverage Report, Monthly Export Import etc

Enhanced Efficiency

Automation of the embroidery planning process streamlines workflows, reducing lead times and improving overall productivity.

Increased Accuracy

Software minimizes human errors in planning and execution, ensuring that designs are embroidered precisely as intended.

Optimized Resource Management

Effective allocation of embroidery machines and labor ensures resources are used efficiently, maximizing output and minimizing downtime.

Real-Time Job Tracking

Many software solutions provide live updates on the status of embroidery projects, enabling quick adjustments and better responsiveness to changes in demand.

Design Integration

Users can easily upload, modify, and manage embroidery designs, ensuring that all team members have access to the latest files and specifications.

Stitch Planning and Management

Detailed tools for planning stitch types, colors, and densities help maintain high-quality standards and consistency across products.

Data Analytics

Analytics features provide insights into production metrics, helping manufacturers identify trends, evaluate efficiency, and make informed decisions for improvement.

Cost Reduction

By optimizing production processes and reducing material waste, manufacturers can lower operational costs, leading to increased profitability.

Scalability

As production demands grow, embroidery planning software can easily adapt to accommodate larger volumes and more complex designs without sacrificing quality.

Improved Collaboration

Integrated communication tools enhance coordination among teams, suppliers, and clients, reducing misunderstandings and improving overall project management.

By utilizing software for garments embroidery planning, manufacturers can enhance their operational efficiency, improve product quality, and maintain a competitive edge in the evolving fashion industry

How Software Generates Smart Report Analytics in Embroidery Planning

Garment embroidery planning software utilizes advanced data analytics to produce insightful reports that enhance operational efficiency. Here’s how it works

Data Collection

The software collects data from various stages of the embroidery process, including job schedules, machine performance, thread usage, and labor efficiency.

Real-Time Monitoring

By tracking production in real-time, the software captures essential metrics such as stitch counts, job completion times, and equipment downtime, providing an accurate overview of performance.

Automated Analysis

Advanced algorithms analyze the collected data to identify trends, patterns, and discrepancies, allowing for quick processing and minimizing the risk of human error.

Customizable Reporting

Users can generate reports tailored to their specific needs, such as production summaries, efficiency metrics, and inventory statuses, helping stakeholders focus on the most relevant information.

Visualization Tools

Data visualization features, including charts and graphs, simplify complex information, making it easier to interpret. These visual aids highlight key performance indicators (KPIs) and areas needing improvement.

Comparative Analysis

The software enables comparisons across different time periods, production lines, or shifts, allowing manufacturers to evaluate changes in performance and identify best practices.

Predictive Analytics

Some solutions incorporate predictive analytics to forecast future production needs and potential challenges based on historical data, facilitating proactive planning and resource allocation.

Integration with Other Systems

Many embroidery planning software options can integrate with other enterprise systems, such as inventory and supply chain management, providing a comprehensive view of operations.

User-Friendly Dashboards

Intuitive dashboards present key metrics and analytics in an easily digestible format, enabling decision-makers to quickly assess performance and make informed choices.

Actionable Insights

The ultimate goal of smart report analytics is to provide actionable insights. Manufacturers can leverage this data to make strategic decisions, optimize workflows, and enhance overall productivity.

By utilizing smart report analytics, garment embroidery planning software empowers manufacturers to improve efficiency, reduce costs, and maintain high-quality standards in their embroidery operations.